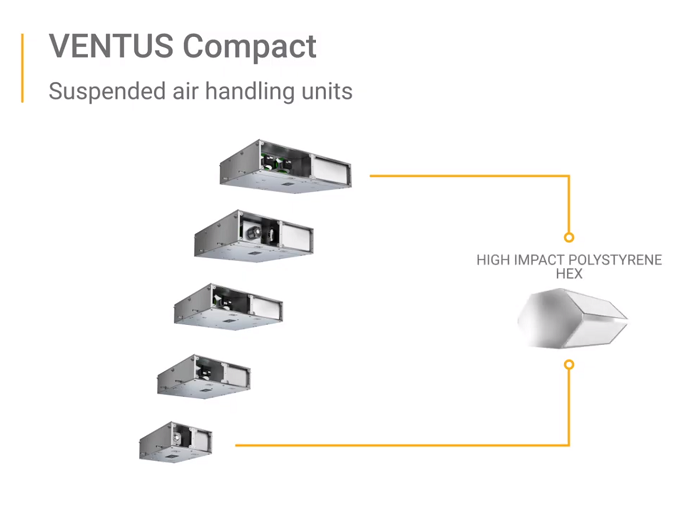

Heat exchangers made of plastics are more and more popular among ventilation and air conditioning manufacturers. This results mainly from the flexibility of creating useful features of these materials followed by functionality of components made of them. The plastic heat exchangers are especially popular among small units, but can be also met in large ones handling even 30 000 m3 /h.

What is HIPS?

This is a polystyrene modified by polybutadiene rubber. The addition of the rubber increases its durability for mechanical impacts and facilitates its thermoforming. This material is:Fully ecological – can be recycled in 100%. The CO2 emission related with its manufacturing is significantly less than in case of plates made of aluminium.

Perfect for contact with food

Humidity resistant

Resistant for diluted acids, eg. Vinegar

The HIPS can be applied in:

Energy recovery systems in air conditioningInternal coating of refrigerated counter and refrigerators

Constructive and decorative elements of commercial stands

Casing of lighting systems

Packages

Transportation pallets

Casing of devices containing electronics

In ventilation systems where highest air stream separation between supply and exhaust is critical. The HIPS exchangers can secure almost 100% of separation thanks to ultrasonic welding and sticking of the plates.

Where high humidity of processed air occurs, followed by intense condensation. eg. balneology and bathrooms ventilation.

Where high hygienic standards must be maintained, eg. food industry

Wherever aluminium exchangers cannot be applied due to highly corrosive contamination of the processed air without high-temperature applications.

Where attractive price is a key to win the job.

The range of air temperatures to be processed by the HIPS exchanger must be within the limit of (-20oC) ¸ (+50oC). That’s why, for ambient air temperatures lower than -20 oC, application of pre-heater located upstream the energy recovery section is recommended.

The HIPS exchangers should not be applied, where chlorine compounds and fat can be met in the processed air.