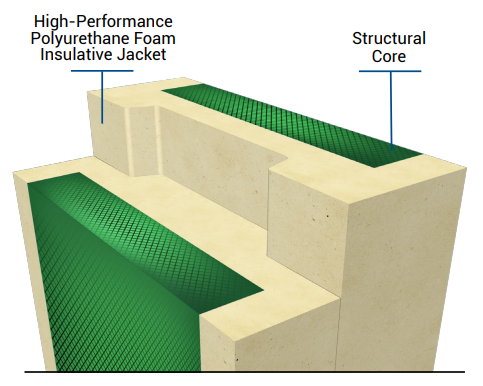

KPS Global has produced a new white paper covering the optimization of R-values and condensation resistance through a polyurethane foam jacket around a structural core. Benefits of improved R-values and condensation resistance include energy savings and improved life cycle of the walk-in unit.

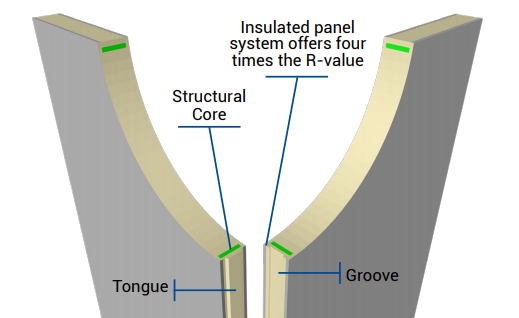

The new white paper follows the launch of KPS Global’s patented FUSIONFRAME, a new insulated panel frame system offering more than four times the R-value, 29.30 vs. 6.25, and comparable structural performance to traditional wood-frame systems. This system eliminates thermal bridging and limits heat gain, condensation development and panel joint icing.

“Keeping unwanted humidity and heat from entering walk-in storage units is the name of the game,” said Mike Eakins, CEO, KPS Global. “The wood frames that have come to define the industry have outlived their usefulness, causing excess energy usage and ongoing maintenance issues from condensation.”

In tests of a 5-inch insulated panel against a 5-inch wood-frame panel, FUSIONFRAME reduced heat gain through the freezer envelope by 50%. This system also eliminates thermal bridging found in traditional wood framing. With tangible improvements in energy efficiency and comparable structural performance to wood, this system is cost-effective and environmentally conscious.

“When heat attacks walk-ins from all directions, it is important to eliminate any weak links that allow the elements inside,” James Costanza, Technical Fellow, KPS Global. “After five years of research, we determined that the ideal frame construction could only be achieved through a structural core with a jacket of foam in a tongue-and-groove joint.”

Read More

18 July 2019

KPS Global Releases White Paper on Walk-In Unit Frame Performance

Related news

Danfoss opens water test lab for tailored nozzle performance valida...

Danfoss has opened a new water test laboratory at its Nordborg production site, offering tailored nozzle performance testing for customers in applications such as humidification, dust suppression, ...

26 Jun 2025

AHRI reports 6.4% rise in April U.S. HVAC shipments

U.S. shipments of central air conditioners and air-source heat pumps increased by 6.4 percent in April 2025, according to the latest data from the Air-Conditioning, Heating, and Refrigeration I...

23 Jun 2025

Daikin invests in Asuene to expand decarbonization services

Daikin Industries, Ltd. has invested in Asuene Inc., a Tokyo-based startup offering CO2 emissions tracking and ESG management services. The investment was made through a third-party allocation of s...

18 Jun 2025

LU-VE Group’s Spirotech plant receives National Export Award in India

LU-VE Group’s Indian subsidiary, Spirotech, has received the National Export Award from the Engineering Export Promotion Council (EEPC), under the Ministry of Commerce, Government of India. The awa...

yesterday

Caverion Austria acquires Lepuschitz Kältetechnik GmbH

Caverion Austria has acquired Lepuschitz Kältetechnik GmbH, a refrigeration specialist based in Wernberg, Carinthia. The acquired company employs 18 people and generates annual revenue of approxima...

yesterday

EVAPCO and CCCTC collaborate on 3D model of dry cooler

EVAPCO has partnered with the Carroll County Career & Technology Center (CCCTC) to support a student-led 3D modeling project based on the company’s eco-Air Series Double Stack Dry Cooler. The c...

27 Jun 2025