Mitsubishi Heavy Industries Air-Conditioning and Refrigeration Corporation (MHI-AC&R) has received an Excellence Award in the Refurbishment Equipment category of the 40th Excellent Energy Saving Equipment Awards of the Japan Association of Refrigeration and Air-Conditioning Contractors (JARAC) for its advancement of energy saving in existing DBS refrigeration units through use of a high-efficiency brine inverter centrifugal chiller. High accolades were also given to the energy saving and carbon emissions reduction derived from installation of the “ETI-ZE25” of a brine inverter centrifugal chiller, as the DBS unit’s heat source.

The JARAC Awards were created to further promote energy saving and environmental protection of refrigeration and air-conditioning equipment by calling for examples of excellence and presenting awards of recognition as a way of contributing to the development and proliferation of energy-saving technologies, and to heighten awareness in related industries toward energy saving and environmental protection. The JARAC Award marks the third consecutive year MHI-AC&R has received an industry award: in 2021 the company was presented a JARAC Excellence Award in the Refurbishment Equipment category (Award-winning equipment: Q-ton Circulation, an air-to-water heat pump), and in 2022 it received the Highest Excellence Award of the Energy Conservation Center, Japan (ECCJ) (Award-winning equipment: GART-ZE75I.HP, a heat recovery centrifugal heat pump).

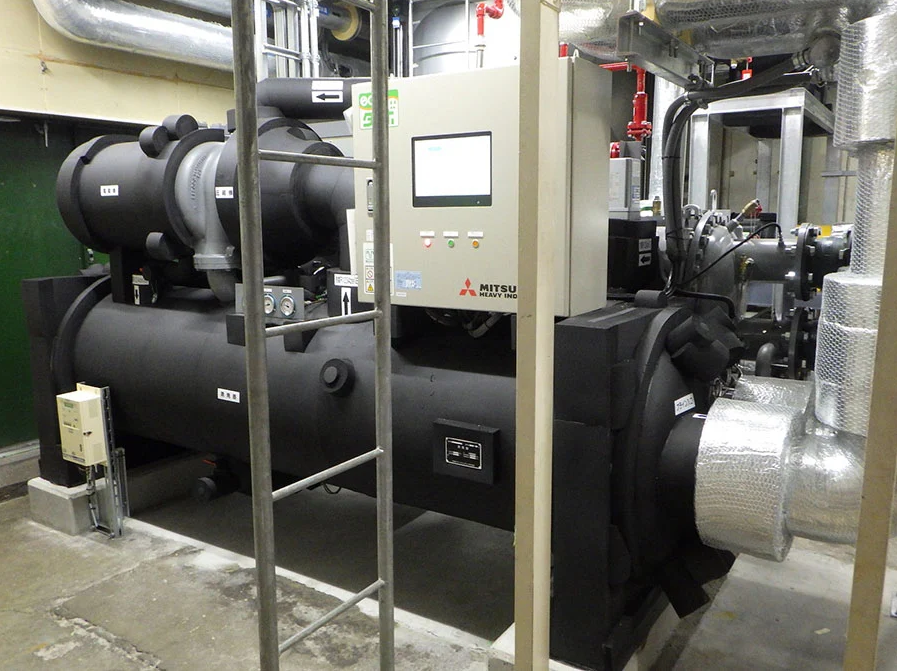

The new JARAC Award was presented in recognition of the energy saving and reduced CO2 emissions, resulting in an improved COP, achieved through installation of the ETI-ZE25, featuring a rated refrigerating capacity of 520kW, as the heat source of a DBS unit in operation at Kanagawa Kankitsu Kako Co., Ltd. (KMK), a producer of diverse beverages in various containers on consignment from major beverage manufacturers, etc. In addition to upgrading the heat source, the cooling system design was also newly modified: use of a waste heat recovery type heat exchanger, whereby cooling water and brine undergo heat exchange, enhanced the responsiveness to load fluctuations of the production equipment, enabled standby operation when the load factor is low, and reduced the number of starts and stops. Compared to the original system, these innovations together resulted in an energy saving equivalent to approximately 43.8kL of crude oil and a reduction of some 79.8 tons of CO2 emissions (both figures corresponding to reductions of 34.7%), resulting in an anticipated electricity consumption saving of near 5.3 million JPY per year.

The ETI-ZE25 is a chiller which was specially developed for low-temperature use for brine specification models, based on the existing ETI Series of chilled-water inverter centrifugal chillers. Through adoption of the HFO-1234ze(E) refrigerant, which features an extremely low Global Warming Potential (GWP) below 1, this chiller’s environmental impact can be significantly reduced. Also, because the new refrigerant is not subject to Japan’s Freon Emissions Control Law, users can obtain operational advantages from reductions of maintenance time and costs, etc.

Going forward, MHI-AC&R will continue providing energy-saving solutions incorporating its efficient centrifugal chillers that contribute to the issues that the customers are facing. By proposing a wide-range of solutions in accordance with market needs, the company will help to achieve a low-carbon society.