bronze partner

30 January 2024

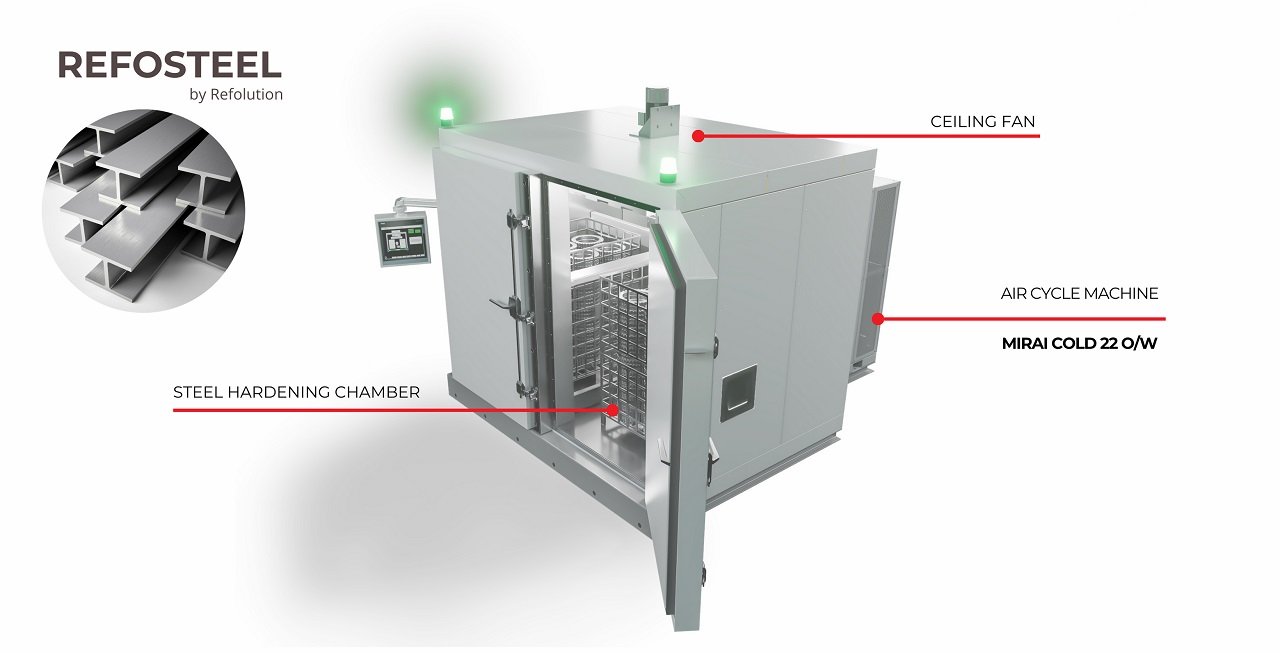

Ultra-low temperature steel hardening system

Cryogenic steel treatment is carried out at temperatures between -70°C and -120°C for one hour. It increases hardness and wear resistance by converting a higher proportion of austenite to martensite. This process is usually performed using liquid nitrogen. The requirement of nitrogen is very high and results in significant operating cost.

MIRAI's business partner Refolution has developed a new concept for a rapid cooling room that uses only air as a refrigerant. Temperatures between -40°C and -120°C are generated by the MIRAI COLD 22 O/W air cycle machine. The cooling room for cryogenic steel hardening consists of two rooms separated by a permeable barrier. Therefore, two different batches can be hardened in one machine. A heat exchange takes place between a new batch and the warm batch before the warm batch must be cooled down to the required temperatures using an air cycle machine. This saves some of the refrigeration capacity required for cooling and reduces operating costs. This solution is more efficient than existing technologies over a wide temperature range. It is also free of regulations, safe for the environment and requires little maintenance as it uses only air as a refrigerant.

Components are typically quenched to -80°C and then reheated to +100°C when hardening steel. This provides the high level of hardness required for many components such as camshafts, gears, razor blades, ammunition, etc.

The system can cool these components to extremely low temperatures. The double door principle allows a large proportion of the energy in a batch to be recovered. The first batch enters through the first door and is cooled to, for example, -80°C. The batch then remains in the system and the next batch is loaded through the second door. Before the refrigeration system starts to cool the new warm batch, the energy is equalized between the batches. Re-tempering takes place in a separate oven rather than in the Refosteel. This saves a considerable amount of energy, as re-tempering an entire room requires a lot of energy.

The integrated cold air-cooling technology from MIRAI Intex enables variable temperatures, a fast-cooling rate and high efficiency. With air as the refrigerant, the system has a low CO2 footprint and is not subject to any current or future regulations regarding the use of refrigerants.

The chamber consists of stable isolation panels with ram protection and is installed on a mobile base frame.

Efficient cold air refrigeration technology from MIRAI Intex is used. This technology is oil-free, has low vibration and uses air as a refrigerant. As a result, it is free of refrigerant regulations and the speed-controlled turbo compressor allows flexible temperature settings down to -140 °C. In addition, a high cooling rate can be achieved if required.

Those systems come with an industrial control unit from Siemens including operating panel, LED lamps and acoustic signaling device. This allows the system to be operated quickly and easily. The system operator receives information about the status of the system via the signal lights. He can also intervene manually in the process via the authorization levels on the operating panel.

The energy can be recovered from previous batches and used to pre-cool the next batch due to the separation of the cold and hot oven and the double chamber system. This can result in energy savings of up to 60 %.

The air in the chamber is used as the refrigerant thanks to the system design of the cold air chiller from MIRAI Intex. The chamber is cooled by drawing in heated air, which is then exhausted via the MIRAI Intex snow catcher. The system enables a continuous process without defrosting and impresses with its high temperature stability.

A ceiling fan specially developed for this application ensures a high circulation rate in the chamber and optimum temperature distribution.

MIRAI's business partner Refolution has developed a new concept for a rapid cooling room that uses only air as a refrigerant. Temperatures between -40°C and -120°C are generated by the MIRAI COLD 22 O/W air cycle machine. The cooling room for cryogenic steel hardening consists of two rooms separated by a permeable barrier. Therefore, two different batches can be hardened in one machine. A heat exchange takes place between a new batch and the warm batch before the warm batch must be cooled down to the required temperatures using an air cycle machine. This saves some of the refrigeration capacity required for cooling and reduces operating costs. This solution is more efficient than existing technologies over a wide temperature range. It is also free of regulations, safe for the environment and requires little maintenance as it uses only air as a refrigerant.

Components are typically quenched to -80°C and then reheated to +100°C when hardening steel. This provides the high level of hardness required for many components such as camshafts, gears, razor blades, ammunition, etc.

The system can cool these components to extremely low temperatures. The double door principle allows a large proportion of the energy in a batch to be recovered. The first batch enters through the first door and is cooled to, for example, -80°C. The batch then remains in the system and the next batch is loaded through the second door. Before the refrigeration system starts to cool the new warm batch, the energy is equalized between the batches. Re-tempering takes place in a separate oven rather than in the Refosteel. This saves a considerable amount of energy, as re-tempering an entire room requires a lot of energy.

The integrated cold air-cooling technology from MIRAI Intex enables variable temperatures, a fast-cooling rate and high efficiency. With air as the refrigerant, the system has a low CO2 footprint and is not subject to any current or future regulations regarding the use of refrigerants.

The chamber consists of stable isolation panels with ram protection and is installed on a mobile base frame.

Efficient cold air refrigeration technology from MIRAI Intex is used. This technology is oil-free, has low vibration and uses air as a refrigerant. As a result, it is free of refrigerant regulations and the speed-controlled turbo compressor allows flexible temperature settings down to -140 °C. In addition, a high cooling rate can be achieved if required.

Those systems come with an industrial control unit from Siemens including operating panel, LED lamps and acoustic signaling device. This allows the system to be operated quickly and easily. The system operator receives information about the status of the system via the signal lights. He can also intervene manually in the process via the authorization levels on the operating panel.

The energy can be recovered from previous batches and used to pre-cool the next batch due to the separation of the cold and hot oven and the double chamber system. This can result in energy savings of up to 60 %.

The air in the chamber is used as the refrigerant thanks to the system design of the cold air chiller from MIRAI Intex. The chamber is cooled by drawing in heated air, which is then exhausted via the MIRAI Intex snow catcher. The system enables a continuous process without defrosting and impresses with its high temperature stability.

A ceiling fan specially developed for this application ensures a high circulation rate in the chamber and optimum temperature distribution.

Related news

Eurovent Certification white paper reports CO2 gas coolers underper...

Eurovent Certification has published a white paper examining how refrigeration heat rejection equipment can perform differently across climate zones and why region-relevant, independently verified ...

24 Feb 2026

CERN starts 1.9 K cooldown of HiLumi LHC test stand

CERN has started the cryogenic cooldown to 1.9 K (-271.3 °C, approx. -456.3 °F) of its 95-metre-long (approx. 312-ft-long) Inner Triplet String (IT String) test stand, a full-scale replica of equip...

04 Mar 2026

Advansor upgrades CuBig II system with higher capacity and efficiency

Advansor has introduced an enhanced version of its CuBig II CO₂ refrigeration system, offering increased medium-temperature (MT) capacity, greater heat recovery, and improved performance for low-te...

19 Jan 2026

Eurovent releases flyer on evaporative cooling and climate change

Eurovent has published a new informational flyer outlining the role of evaporative cooling technologies amid rising global temperatures and increasing cooling demand. The publication, titled “E...

03 Mar 2026

Hillphoenix launches Next Generation Flex Mini CO2 system in the US

Hillphoenix, part of Dover Food Retail and Dover, has launched the Next Generation Flex Mini, a CO2 transcritical refrigeration system designed for food retail and industrial applications. Th...

06 Mar 2026

Nidec develops prototype liquid-cooling CDU for AI data centers und...

Nidec Corporation has announced the development of a prototype Coolant Distribution Unit (CDU) based on the Google Open Compute Project (OCP) specification for Project Deschutes. The prototype was ...

17 Dec 2025