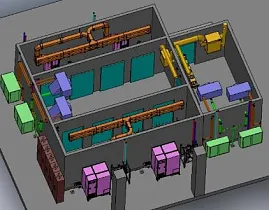

Ultra Refrigeration has developed a high efficiency CO2 refrigeration pack with full heat recovery that provides for the total comfort heating and air conditioning requirements of convenience stores. The company’s Integrated Power Pack (IPP), based on BITZER’s Ecoline CO2 reciprocating compressors, has been installed in four convenience stores in Lincolnshire as part of the retailer’s efficiency drive and carbon reduction programme.

The system captures heat from the high temperature discharge side of the pack by passing hot gas through a compact contraflow heat exchanger, transferring heat to a water-based heating system. Hydronic fan coils provide comfort heating and cooling for the store and adjoining warehouse facilities.

Hot water is also used to supply the over-door air curtain on the store’s main entrance, which operates constantly during opening hours, saving up to 14kW of electrical energy.

The IPP systems deployed deliver a total of up to 90kW of heating and 40kW of comfort cooling, although the design is scalable and can be configured for larger applications if required.

With efficiency boosted by significant energy savings on the heating side, the system has a pay-back on investment of around two years. In addition to energy savings and the much lower environmental impact, a further benefit of the system is that only low pressure pipework circulates within the store, avoiding any risks associated with in-store high pressure systems.

The stores served by the packs typically have around 22kW of high temperature (HT) refrigerated cases and 6kW of low temperature (LT) units. If the pack’s current cooling requirement is not sufficient to provide the minimum design load to heat the store, a forced load evaporator is brought into circuit to generate the heat required – achieving the required operating conditions more efficiently than would be the case with conventional air source heat pumps.

The packs installed to date are based on four BITZER Ecoline CO2 compressors, one dedicated to the LT side (Ecoline model 2HME-3K-40S), two handling the HT side (Ecoline model 4JTC-15-40P), and one covering comforting heating and cooling duties (Ecoline model 4HTC-20-40P) – with the option for load-sharing, depending on conditions.

In addition to use in food stores, the pack lends itself to applications in industrial process projects requiring pre-heating of water or space heating. It has also been used in a low temperature climatic chamber for testing engines down to Siberian temperatures as low as -45deg C, with reclaimed heat being used to warm the facility’s control centre and workshop.

The move to CO2 is being driven by the phase-down in high Global Warming Potential (GWP) refrigerants under the F-Gas Regulation. Carbon dioxide has a GWP of just 1, compared with 3922 for R404A and 1300 for R-134a, both outgoing high GWP refrigerants.