gold partner

27 October 2022

Secop has developed Ultra-Low Temperature Active Medical Cooling Technology

Secop has developed the technology for an ultra-low temperature mobile cooling system. This system is optimized for the last mile of distribution for the new generations of vaccines and offers mobile operation even in high ambient conditions such as in tropical regions.

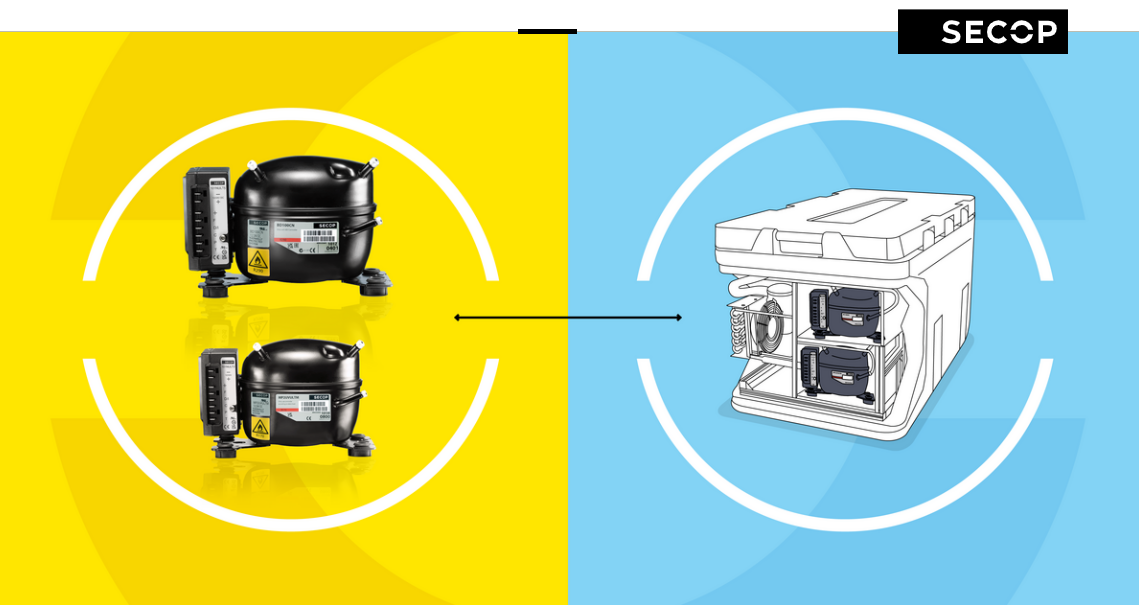

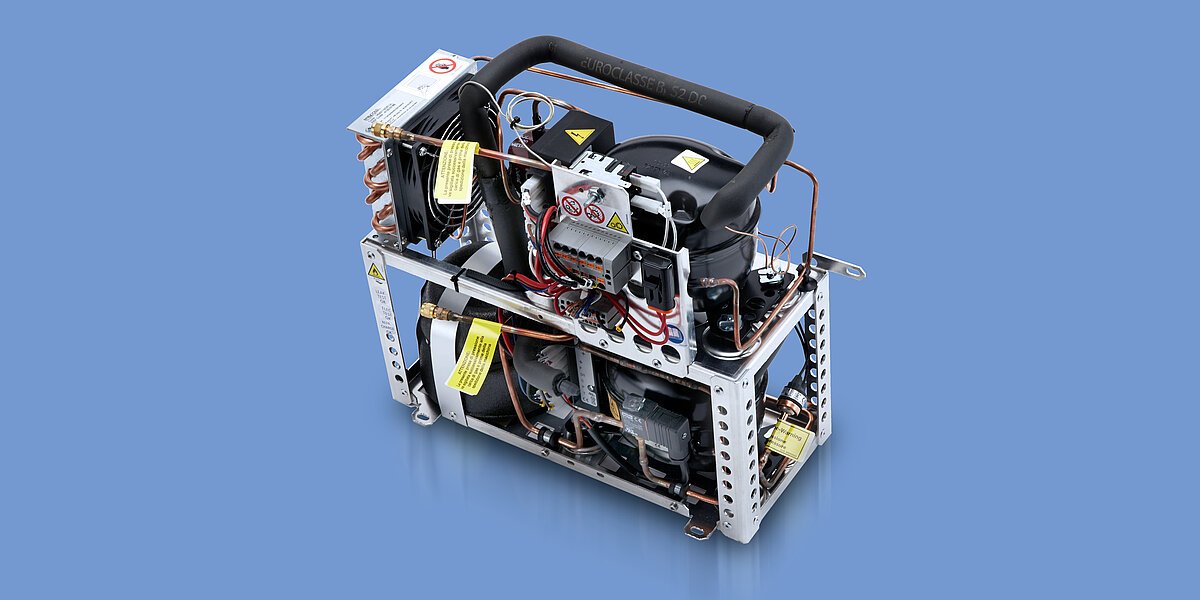

This dedicated condensing unit features a compressor cascade solution with a MP2UVULTM (low stage) and a BD100CN (high stage) compressor and takes advantage of Secop’s experience in medical applications, vaccine solar freezers, and mobile solutions and combines all of these applications.

Battery-driven active cooling systems for mRNA-based vaccines provide many advantages compared to existing passive cooling (dry ice) transport boxes. Active systems offer temperature control, do not need huge quantities of dry ice, are re-usable, do not waste tons of CO2, and prevent vaccine wastage.

They are suitable for any distribution point, including in remote areas where the availability of CO2 cannot be guaranteed or ambient conditions are too severe.

This dedicated condensing unit features a compressor cascade solution with a MP2UVULTM (low stage) and a BD100CN (high stage) compressor and takes advantage of Secop’s experience in medical applications, vaccine solar freezers, and mobile solutions and combines all of these applications.

Battery-driven active cooling systems for mRNA-based vaccines provide many advantages compared to existing passive cooling (dry ice) transport boxes. Active systems offer temperature control, do not need huge quantities of dry ice, are re-usable, do not waste tons of CO2, and prevent vaccine wastage.

They are suitable for any distribution point, including in remote areas where the availability of CO2 cannot be guaranteed or ambient conditions are too severe.

Benefits:

- Safe active fully automated mobile solution based on a 2-stage speed controlled compressor cascade system with a flexible temperature range from -20°C to -86°C even in tropical ambient conditions (43°C)

- Ideal solution for mains voltage independent transport and storage of mRNA-based COVID-19 and Ebola vaccines and CGT specimens

- Low energy consumption and fast pull-down time using low GWP green hydrocarbon refrigerants

- Reliable and precise temperature setting and control and reduced risk of wasting temperature sensitive specimens and vaccines

- Reliable long-lasting system with low TCO life cycle

- Designed for AC/DC global voltage range and optimized for low grid areas

- Easy °CCD controller customization via Tool4Cool software

Related news

Secop introduces KL-CNQX tropical compressors for propane cabinet s...

Secop has launched new tropical KL-Series compressors, including the KL-CNQX, targeting the next generation of light commercial cabinets using environmentally friendly refrigerant propane. The comp...

02 Mar 2026

Epta launches new Iarp Alba freezers for foodservice and retail

Epta has unveiled two new negative-temperature display cases under its Iarp brand — Alba 43 and Alba 45 — targeting the Food & Beverage and Ho.Re.Ca. sectors. Presented as successors to the Gle...

17 Dec 2025

Copeland introduces CO2 scroll compressor with dynamic vapor injection

Copeland has launched a transcritical CO2 scroll compressor with dynamic vapor injection (DVI) technology in North America. The new solution is designed for distributed CO2 refrigeration syst...

09 Dec 2025

Trane launches R290 air-to-water heat pumps for EMEA and ANZ

Trane (a brand of Trane Technologies) has launched two air-to-water heat pumps using R290 refrigerant: FLEX N HP and ARIES N HP. The company said the new units expand its R290 portfolio for custome...

26 Feb 2026

Williams launches UK's first multi-temperature refrigeration units

Williams Refrigeration has introduced the Jade MultiTemp range of counters and cabinets, claimed to be the first in the UK foodservice market to offer multi-temperature capability in a single unit,...

12 Feb 2026

Daikin launches full R-290 range up to 2,000 kW

Daikin has introduced a complete R-290 (propane) product range covering capacities from 17 to 2,000 kW (approx. 58,000 to 6.82 million BTU/h). The portfolio includes two families: the EWA(Y)K-CZ mo...

03 Mar 2026