A new low carbon CO2 refrigeration system from J & E Hall is helping a leading food processor expand production, cut global warming emissions and meet the challenge of the F-Gas Regulation step downs. To cope with a growing demand for its meat and fish products, Campbells has built a new freezer room at its processing plant at Linlithgow near Edinburgh.

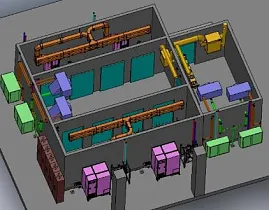

A temperature of around -18°C keeps products in perfect condition before they are sold to customers. Two 20 kilowatt J & E Hall CO2 refrigeration packs support the freezer room to ensure that temperatures are maintained at the correct temperature.

The F-Gas Regulation is having an increasing effect on the food processing industry and forcing installers and end users to switch to low global warming potential refrigerants. CO2 is a natural refrigerant with zero global warming potential which makes it a good choice for the food processing industry. CO2 has a wide temperature range which also makes it a versatile refrigerant.

J & E Hall has a long history of providing bespoke refrigeration solutions for the food processing industry and their reputation for innovation, reliability and good customer service persuaded Campbells that they were the right choice for the job.

Gary Barrett, J & E Hall Glasgow Centre Supervisor, took the lead on the project at Linlithgow. He said: “CO2 technology has moved on so much in recent years that we were confident that this natural refrigerant would do a good job for Campbells. CO2 systems are now cheaper to install and these two CO2 packs were a long term solution which removed the worries of the F-Gas Regulation and constant concerns about leak testing.”

The new refrigeration packs on site work directly with the evaporators and no intermediate cooling is needed which made it easier for the system to be installed and commissioned.

The customer is delighted with the new freezer room and the new refrigeration system, as Stephen Sweeney, Finance Director of Campbell’s Prime Meat, explained: “We did some research in the industry and J & E Hall came very highly recommended. We had used other refrigerants on site but CO2 with its green credentials proved to be the most attractive option.

“We were looking for a contractor who could deliver the job on time and on budget but also bring some imagination when required. This led to us going for the CO2 option recommended by J & E Hall instead of the high global warming potential gases which we had used on site in the past.

J & E Hall was one of the first refrigeration installers to recognise the potential of CO2 in the food processing industry and the company believes that this natural refrigerant has a big future as the pressure on end users to be more carbon friendly continues to grow.