At Chillventa in 2018 HB Products launched a new revolutionary HBX Vapor Quality Sensor which can optimize the evaporator control and eliminate super heat. Since Chillventa HB Products has been busy delivering Vapor Quality sensors to large players in the marked. “We have great interest in the product, and our customers are extremely satisfied and can clearly see the potential in the Vapor Quality sensor.”, Claus Munkholm, Sales Manager at HB Products, proudly explained.

HB Products has tested the Vapor Quality Sensor on a trans critical CO2 refrigeration system and compared the results with a system controlled by a conventional super heat controller and the results are clear.

“With a system controlled by a Vapor Quality sensor it is possible to raise the suction pressure with 8 K and save up to 20 % energy compared with a system with conventional super heat control”, Michael Elstrøm, Director & Technical Manager at HB Products said.

To get a third party verification of the striking results HB Products has entered into collaboration with Gent University in Belgium, who will perform several tests on the Vapor Quality sensor.

“We have chosen Ghent University as our academic partner because it is a top 100 university with excellent laboratory facilities, and because they have many years of experience in using and applying the capacitive measurement principle in their research. We have great confidence in their professional way of doing research and we are looking forward to receiving the report”, Michael Elstrøm said.

How can the Vapor Quality Sensor improve energy efficiency?

Energy efficient systems are normally designed and constructed as overfeed systems, here the circulated refrigerant rate “CR” normally is up to 3 times higher compared to a direct expansion system. With a Vapor Quality Sensor, you can achieve semi flooded operation with a simpler system design. This means that you can get even better efficiency at a lower cost and with a significant lower refrigerant charge.

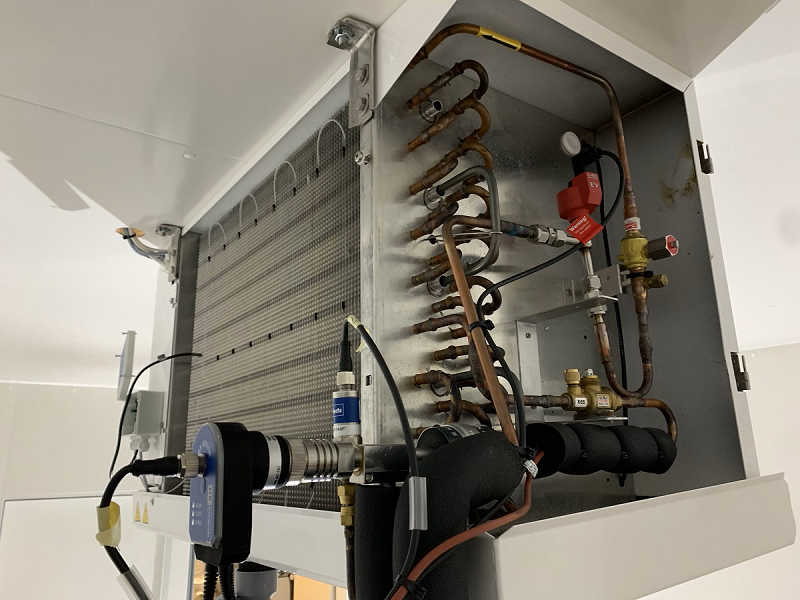

The evaporator is a major component in a refrigeration system, and an efficient evaporator plays a key role in saving energy. With the Vapor Quality Sensor, you can achieve balanced evaporator control by mounting the sensor in the evaporator outlet and control an electronic expansion valve directly with the built-in PI-control. Superheat can be eliminated, and evaporator capacity will be increased because of semi-flooded operation, where the hole evaporator area is utilized for evaporation.

At the same time the installation cost is reduced. as the external control or PLC is not needed, to make it simple and cost effective there is also a built-in driver for stepper motor or PWM control valves.

Vapor Quality Sensor – now in a new improved version

New knowledge and wishes from the market for measuring Low Vapor Quality have resulted in a new design optimized for measuring both HI and LOW Vapor Quality (VQ), next generation VQ sensors from HB Products measure from”X” wet 0.2 to dry 1.0. The new sensor design is also less influenced by oil accumulation during low load.