Direct-to-Chip (D2C) Cold Plate In-Rack CDU & CDM is a cooling solution specially designed for server cabinets with high cooling requirements.

Efficient heat dissipation: The Direct-to-Chip (D2C) Cold Plate In-Rack CDU & CDM uses water-cooling technology to provide more efficient heat dissipation than traditional air cooling. The water cooling system quickly removes heat from the servo components and transfers it to an external cooling system, ensuring that the servo remains within the ideal operating temperature range.

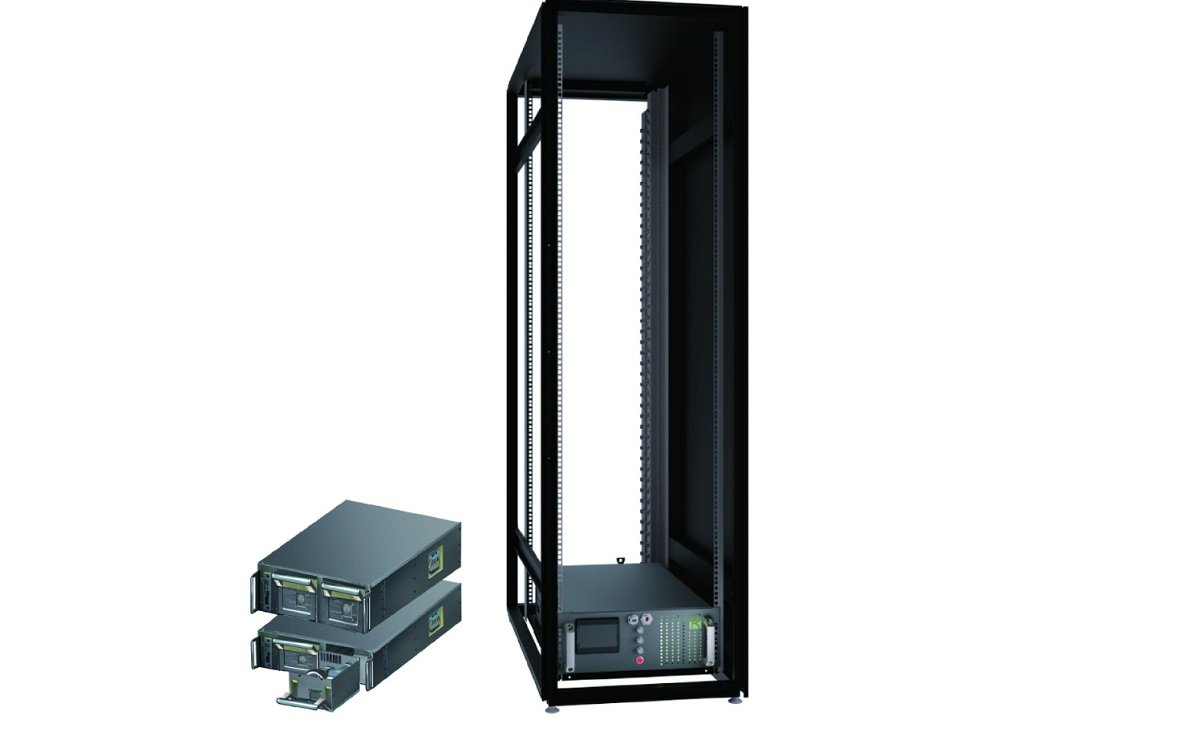

Space saving: The cooling unit of the Direct-to-Chip (D2C) Cold Plate In-Rack CDU & CDM is usually installed on the back or side of the server cabinet, and is closely integrated with the server structure. It saves valuable rack space, enables a smaller overall system footprint, and provides higher rack density compared to traditional cooling solutions.

Quiet operation: Compared with fan cooling, the running noise of the Direct-to-Chip (D2C) Cold Plate In-Rack CDU & CDM is lower. The running sound of the water pump in the water-cooling system is relatively small, which reduces the interference of noise to the working environment, and is especially suitable for places that require a low-noise environment, such as offices or laboratories.

Stable cooling effect: The Direct-to-Chip (D2C) Cold Plate In-Rack CDU & CDM can provide more stable cooling effect. Since water has high thermal conductivity, it can effectively disperse heat and reduce hot spots. This helps improve the overall performance and reliability of the server, and extends its lifespan.

Scalability: The design of the Direct-to-Chip (D2C) Cold Plate In-Rack CDU & CDM usually takes scalability requirements into consideration. It can be customized according to the number of servers and cooling needs to ensure that the system can accommodate future expansion.

Features & Advantages

- Liquid-Liquid cold plate cooling solution

-

Power Usage Effectiveness (PUE) is lower 1.2

-

Reliable Magnetic Pump

-

Suitable for high computing servers in

-

(CDU) In Rack OCP21' with hot swapping CDU